Otoplastics are custom-made hearing protectors specifically designed to protect the ears from harmful noise. They are commonly used in environments with high noise levels, such as construction sites, factories, concerts or even while motorcycling.

What sets otoplastics apart is their ability to be custom-made for the wearer, resulting in a comfortable fit that can be worn all day without discomfort. This customisation feature not only ensures comfort, but also an effective seal that significantly reduces noise levels.

Interchangeable filters play a crucial role in otoplastics because they allow the user to adapt the degree of sound protection to different environments. This is essential because not all situations require the same protection. For example, a loud concert environment may require higher attenuation than while working on a construction site where conversations still need to be heard. Our versatile filters provide this versatility, making otoplastics a valuable and customisable solution for hearing protection in a variety of environments.

Otoplastics, such as those made by Ronell, are designed to both protect and preserve important environmental sounds during work activities. Instead of a complete attenuation of sounds, which may be undesirable in some situations, Ronell filters are characterised by an ingenious sound channel equipped with a filtering system.

This channel is designed to attenuate sounds based on their pitch, filtering out annoying noise while letting important sounds such as voices, sirens or horns through.

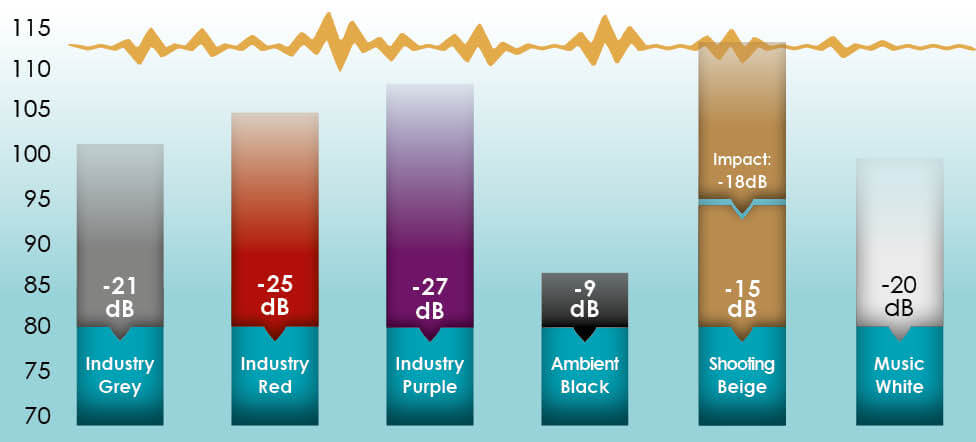

Ronell offers a range of filters that vary in attenuation, each suitable for different working environments and noise levels. The aim is to provide optimum attenuation that reduces the average daily noise level to around 80 decibels, which is considered safe for long-term noise exposure.

Here are some of the filters offered by Ronell, along with their attenuation capabilities:

Suitable for work with noise levels averaging up to 101 decibels per day.

Ideal for activities such as grinding, jigsaws or motorcycling at speeds of up to 100 km/h.

Designed for work with noise levels averaging up to 105 decibels per day. Suitable for tasks such as lawn mowing, chainsaws or working near a helicopter.

Recommended for work with noise levels averaging up to 107 decibels per day. Suitable for situations such as using a pressure washer, mower or angle grinder.

Specially designed to create quietness in environments with ambient noise.

Ideal for use while travelling, sleeping or working in open-plan offices.

Developed for use in shooting sports. Attenuation of standard 15 decibels, but offers additional attenuation of up to 33 decibels during the shot due to air pressure.

Suitable for use at concerts and events.

Provides 20-decibel attenuation to reduce exposure to loud music.

*Grey, Red and Purple are officially certified for 'EN 352-2:2002' and the '(EU)2016/425'. These filters are therefore suitable for the workplace.

If you are interested in exploring the possibilities of Ronell filters for your specific needs and working environment, we warmly invite you to contact us. Our expert team is ready to advise you on which filter is best suited to your situation and answer any questions you may have.

Moreover, we also offer the option of custom-made otoplastics, fully tailored to your unique anatomy and working conditions. With our custom-made solutions, you can count on a perfect fit and optimal sound protection.

Contact us today and find out how Ronell can help you protect your hearing.

Our hearing advisors work in several regions. You have a permanent contact person and we are quickly on location if necessary.

Trapezium 400

3364 DL Sliedrecht