In the workplace, workers are regularly exposed to noise pollution, which poses a significant risk of hearing damage. Prolonged exposure to noise, chemicals and vibrations can lead to hearing loss and other auditory problems. To prevent this, it is essential to take the right measures and use hearing protection.

This blog focuses on the importance of protecting hearing in the workplace and introduces an effective solution in the form of professional otoplastics, such as those from Ronell. Otoplastics offer custom-made hearing protection that is both comfortable and effective at reducing noise thresholds, while still allowing important ambient sounds to pass through.

>> View Otoplastics from Ronell

What are the risks to hearing?

In the workplace, there are several risks of hearing damage that workers may be exposed to. Some of the main risks are:

Noise!

Exposure to prolonged or extreme noise is a common cause of hearing damage in the workplace. It can occur in industries such as construction, metalworking, aviation, shipping, agriculture and the music industry. Machinery, tools, engines, ventilation systems and other equipment can produce noise levels harmful to hearing.

Still keep communicating in the workplace during noise? Then choose earplugs with a communication solution.

Chemicals that affect hearing

Some chemicals can be harmful to hearing when inhaled, absorbed through the skin or entering the body through other routes. Exposure to solvents, such as toluene and styrene, or to certain metals, such as lead and mercury, can cause hearing damage.

Vibrations and vibration are a major risk

Prolonged exposure to vibrations, such as those caused by heavy machinery, tools or vehicles, can cause hearing loss. This is often seen in industries such as construction, mining, agriculture and transport.

Traumatic, sudden noises

Workers in certain occupations may be exposed to unexpected loud noises, such as explosions or gunshots. This can cause acute hearing damage, such as sudden hearing loss or tinnitus (ringing in the ears).

Protection starts on the shop floor

It is important for employers to take measures to provide employees with protect against these risks. This may include using hearing protection, regulating noise levels, providing training on hearing protection and minimising exposure to harmful chemicals and vibrations. Workers should also be made aware of the risks and be aware of proper safety measures to prevent hearing damage.

What is there to do?

To protect the ears from noise pollution in the workplace, the use of hearing protection devices, such as otoplastics, is essential. Here are some steps you can take to prevent hearing damage.

1. Awareness

Be aware of the risks of noise in the workplace and the importance of hearing protection. Understand that prolonged exposure to high noise levels can cause hearing damage. In fact, occupational risks are listed in the highest category of occupational risks according to the European Union. As an employer, it is very important to comply with the laws and regulations for this.

>> Read more about hearing damage laws and regulations

2. Risk assessment

Conduct a thorough risk assessment to identify the sources of noise pollution in your working environment. Measure noise levels and determine what measures are needed to reduce noise exposure.

3. Hearing protection equipment

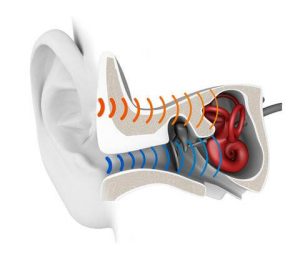

Choose the right hearing protection equipment based on the specific needs of your working environment. Professional otoplastics, such as those made by Ronell, can be an effective solution. Otoplastics are custom-made hearing protectors that fit comfortably in the ear and provide noise reduction while still allowing ambient noise to pass through. They are often used in noisy work environments where communication and warning signals are important.

4. Training and instructions

Ensure that employees receive proper training and instructions on the correct use of hearing protection devices, including otoplastics. Teach them how to insert, remove and maintain otoplastics correctly. Emphasise the importance of consistent use of hearing protection during noise exposure.

5. Maintenance and replacement

Otoplastics and other hearing protection devices should be regularly inspected, cleaned and maintained according to the manufacturer's instructions. Check for wear or damage and replace them if necessary.

6. Monitoring and compliance

Ensure that regular checks are carried out to check whether workers are actually wearing hearing protection and whether it is functioning adequately. Encourage compliance and stress the importance of protecting hearing.

Everything well organised? Choose Ronell Hearing Consultants

Why settle for less? Choose the most valued earplugs, loved by workers all over the world. With more than 20 years of experience and our own laboratory, we are the experts in finding the perfect otoplastics for your situation.

Using our advanced 3D technology, we create a fit that fits like a glove. Comfortable and with optimal attenuation, our otoplastics offer the ultimate protection. Increase your employees' motivation to wear hearing protection and let them enjoy a noise-free working environment.

Our dedicated consultants are ready to help you every step of the way in implementing hearing protection in the workplace. From inventory to creating support, we are happy to think along with you. With us, we have an all-in price for guaranteed hearing protection. No hidden costs, no hassle. You can focus entirely on protecting your employees.

Curious about what we can do for you? Contact us today and discover the possibilities of high-quality hearing protection.